SOD-120-2 | SOD-120-2-OEM |

|

|

|

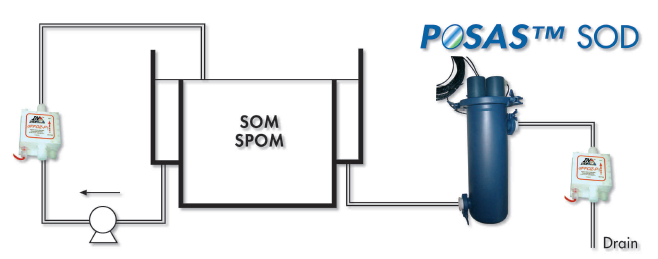

Dissolved Ozone Destruct Unit SOD to Integrate / Upgrade into a Wet Bench or Spray Tool

Ozone is widely used in the Semiconductor Industry, so draining of water and acids containing Ozone is a common problem. As Ozone is too dangerous, Ozone has to be destroyed before it leaves the equipment into the drain system of a FAB. This UV based Ozone destruct unit can be integrated into the wet equipment. Ozone can be effectively removed down to harmless levels below 1ppm. This means the drain will last longer, no Ozone outgasses from the solution, and therefore no Ozone is distributed on the FAB via the drain.

UV based Ozone Destruct Unit SOD-120-2-OEM - Coated on the Interior and Exterior

UV treatment chamber with negative irradiation geometry

| Material | 1.4404 according to DIN 11850 |

| Coated with Safecoat 1348 (dark blue) on the interior and exterior | |

| Connections | 1" Flaretek, others available |

| seals PTFE, Kalrez, / Viton (no contact to fluid!) | |

| Unloaden weight | app. 9 kg |

| Mounting direction | can be mounted vertically or horizontally |

Dimensions

| Height | 550 mm |

| Flange distance | 300 mm |

| Diameter | 237 mm |

Operating Conditions

| Water temperture | 5 - 60 °C |

| Ambient temperature | max. 30 °C |

| Max. operating pressure | 4 bar |

| Pressure drop | <0.02 bar |

| Degree of protection | IP 65 |

| Operating voltage | 120 or 240 V; 50/60 Hz |

| Connected load | 270 W |

UV emitter

| Number | 2 pieces |

| Low pressure emitter | 120 W |

| Radiant flux 254 nm | > 22,8 W |

| Operating life | 8,000 h |

| Cable | 6 m long, PTFE |

| Protective sleeve | 2 Pieces (Material: quartz) |

Electronic ballast (EB) 2 x120 W (double EB) Temperature sensor (1 threshold at T = 80 °C) available

Further Specifications

| Flow rates | 1 -20 l/min. |

| Maximal service life (fluid-filled, no flow) | 2 h |

| Ozone concentration in the effluent | < 1 ppm |

| Incoming ozone concentration | 10 - 250 ppm |

| Ozone reduction | > 96 % |